Top China Manufacturer of Plastic Syringe Needles for Quality Healthcare

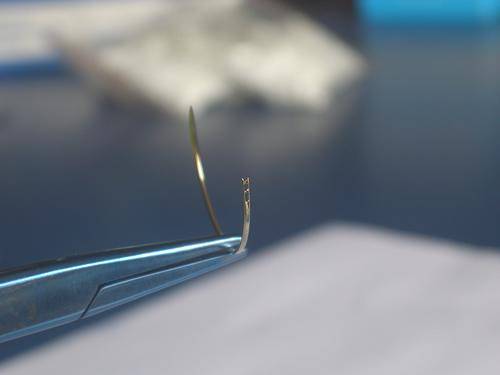

When sourcing high-quality plastic syringe needles, I've found that reliability and precision are key. In our search for the best manufacturers in China, we take pride in delivering products that meet stringent industry standards. Our plastic syringe needles are designed for exceptional performance, ensuring seamless functionality for various medical applications. These needles feature smooth, consistent tips that minimize discomfort, making them ideal for both professional and personal use. Our commitment to quality means each needle undergoes rigorous testing before it reaches your hands. Plus, as a partnered supplier, I can ensure timely delivery and flexible order quantities, tailored to your needs. Choosing the right manufacturer can be daunting, but our transparent processes and competitive pricing make it easier. If you're looking for a dependable source of plastic syringe needles, consider us your go-to choice in the market. Let’s elevate your operations with quality products today!

Plastic Syringe Needle Manufacturer in 2025

As we look ahead to 2025, the demand for high-quality plastic syringe needles continues to rise in the global healthcare market. This surge is driven by an increasing focus on patient safety, the growth of the pharmaceutical industry, and the ongoing need for effective medical devices in a variety of applications. Notably, plastic syringe needles offer numerous advantages, including reduced risk of infection, enhanced patient comfort, and the versatility needed for various healthcare settings. Manufacturers are innovating to meet the evolving needs of healthcare professionals, focusing on precision engineering and the use of biocompatible materials. As regulatory standards become more stringent, the emphasis on quality and compliance is paramount. To ensure optimal performance and safety, suppliers are committing to rigorous testing protocols and certifications. Collaboration with healthcare providers allows manufacturers to gather invaluable feedback, facilitating the continuous improvement of their products. For global purchasers, understanding the landscape of syringe needle production is essential. Prioritizing partnerships with manufacturers that prioritize quality assurance and sustainable practices will ensure a reliable supply chain capable of meeting future demands. As the industry evolves, staying informed about technological advancements and market trends will be crucial in making effective procurement decisions and ultimately improving patient care worldwide.

Plastic Syringe Needle Manufacturer in 2025

| Material Type | Needle Gauge | Length (mm) | Sterilization Method | Certification | Production Capacity (units/year) | Target Markets |

|---|---|---|---|---|---|---|

| Polypropylene | 21 | 40 | Ethylene Oxide | ISO 13485 | 5,000,000 | North America, Europe |

| Medical Grade Plastic | 23 | 30 | Gamma Radiation | CE Marking | 3,000,000 | Asia, Africa |

| Polyethylene | 25 | 50 | Steam Sterilization | FDA Approved | 4,000,000 | South America, Australia |

Related Products